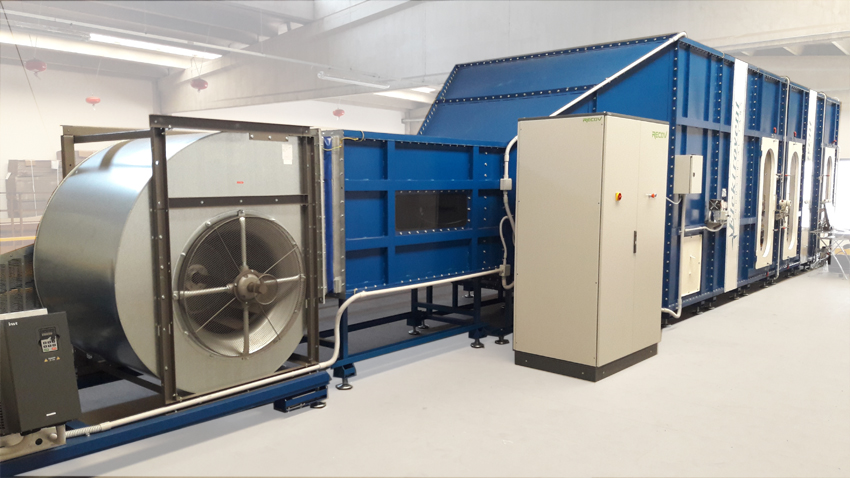

We design and build wind tunnels to measure the performance of all objects through an air flow, either actively (fans, thermal or other machines) or passively ( filters, recuperators or other).

Our technical departments are able to deal with the development of tailor-made projects , elaborated on the basis of the Customer's needs, adopting the most appropriate technological solutions on a case-by-case basis.

Design and construction of wind tunnels: regulatory compliance

Our wind tunnels comply with the AMCA 210 regulations (reference legislation in the US for the study of aeraulic performance) and ISO 5801 (equivalent legislation in the field international).

They are produced both in Outlet Chamber setup (fig. 12 AMCA 210 / fig. 41 ISO 5801) and in Inlet Chamber Setup (fig. 15 AMCA 210 / fig. 40 ISO 5801) . Furthermore, they are supplied complete with acquisition system and management and automation software .

RecoV wind tunnels: measurement accuracy

Thanks to constant development, our galleries ensure high standards of measurement, making it possible to accurate measurements even at very low flow rates and high pressures .

The galleries allow to test all physical quantities with high accuracy:

- air flow

- static, total and dynamic pressures

- mechanical and electrical power

- rotation speed

- mechanical and electrical efficiencies

- currents, voltages, powers and power frequency

- power and sound pressure

- air density and temperature

- motor heating by measuring the electrical resistance of the windings

Features of management and measurement software

The measurement and management software was and is developed to simplify the test work , report creation and search for evidence . All data is saved on the database: master data of the test subject, laboratory set-up, measurements, calculations and analyzes and polynomials of the test curves.

Through an intuitive and multilingual interface it is possible to set the laboratory set-up by selecting:

- measurement range for flow and pressure

- automatic opening of calibrated nozzles

- electrical or mechanical power supply

- single-phase or three-phase DC or AC power supply

- frequency (0-400 Hz)

- voltage (0-1000V)

- mains or inverter power

- partialization of the aeraulic load

Wind tunnel: cost and estimates

For a first contact or to request more information on the RecoV services for wind tunnel construction and design, simply click on the "Contact Us" button or visit the Contact section.